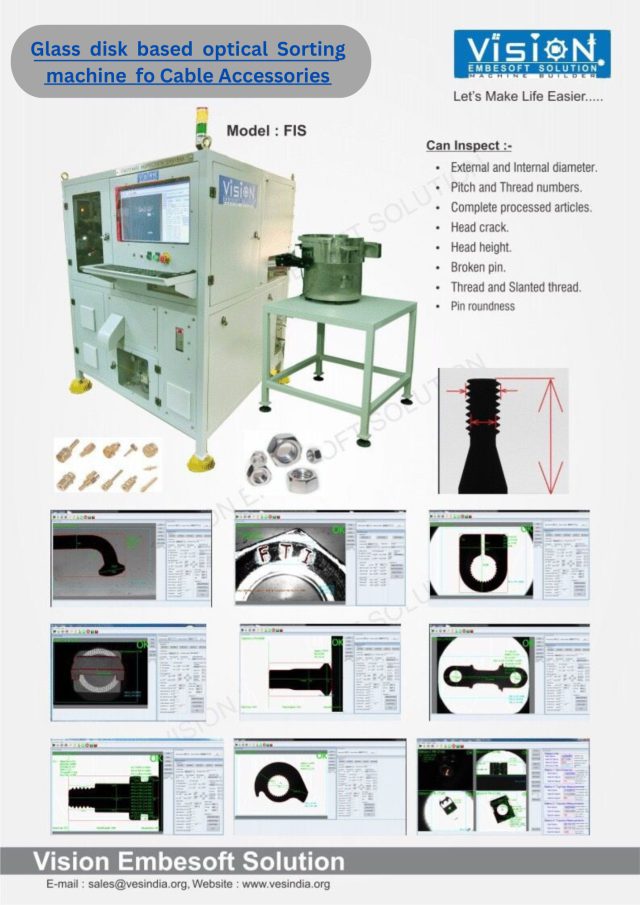

Optimizing Cable Accessories Production with Advanced Glass Disk Optical Sorting Machines for Cable Accessories

In today’s fast-paced manufacturing world, precision and efficiency are key to producing high-quality products while minimizing waste and maximizing output. When it comes to Cable Accessories production, integrating advanced optical sorting machines specifically designed for glass components is a game-changer. In this post, we’ll explore how cutting-edge technologies like glass disk-based optical sorting machines for Cable Accessories can enhance your production line and ensure unparalleled quality control.

Why Choose Glass Disk-Based Optical Sorting Machines for Cable Accessories?

Cable Accessories, especially those incorporating glass components, require precise sorting to ensure uniformity and quality. A glass disk-based optical sorting machine can identify imperfections that are invisible to the naked eye, such as surface defects, cracks, and dimensional variations. This automated process not only speeds up production but also reduces human error, ensuring each Cable Accessories meets stringent quality standards.

Benefits of Glass Disk Optical Sorting Devices for Cable Accessories Manufacturing

- Accuracy and Precision: Utilizing a glass disc optical sorting device for automated glass disk quality control machine for Cable Accessories ensures that even the smallest imperfections are caught before reaching the assembly line.

- Enhanced Visual Inspection: With a glass disc optical inspection system for Cable Accessories, manufacturers can automatically detect surface defects, chips, or scratches on glass components, ensuring only flawless parts move forward.

- Real-Time Quality Control: Glass disk visual inspection machines for Cable Accessories provide continuous, real-time monitoring of production, improving overall efficiency and reducing downtime.

- Improved Production Speed: High-performance equipment like the high-speed optical sorter of glass discs for Cable Accessories can handle large volumes of parts at impressive speeds, allowing manufacturers to meet tight deadlines without compromising quality.

How Precision Sorting Systems Ensure Top-Quality automated glass disk quality control machine for Cable Accessories

When producing Cable Accessories, accuracy is essential. A precision glass table sorting machine for Cable Accessories ensures that every component is measured and sorted to exact specifications. These machines utilize high-accuracy glass disc sorting equipment for Cable Accessories, ensuring no defective pieces make it through the production process, resulting in a higher-quality final product.

Cutting-Edge Vision-Based and Image-Based Sorting Systems

The evolution of technology has brought us sophisticated tools like the glass disk vision-based sorting equipment for Cable Accessories and glass disc image-based sorting systems for Cable Accessories. These machines use advanced vision technology to compare each part against pre-set criteria, guaranteeing consistency across production.

With these systems in place, manufacturers can enjoy:

- Automated, hands-off inspection: A fast optical sorting machine of glass disks for Cable Accessories can analyze parts much faster and more accurately than manual inspection.

- Consistent results: The use of automated glass disk quality control machines for Cable Accessories ensures consistent and reliable inspection, with zero human error.

Automation for Superior Results

As manufacturing evolves, automation becomes more critical. Machines like the automated glass disc inspection and sorting systems for Cable Accessories allow businesses to streamline operations, cut labor costs, and improve product quality. These systems can integrate with existing production lines, providing seamless, real-time quality control that keeps operations running smoothly.

Conclusion

Investing in a glass disk-based optical sorting machine for Cable Accessories manufacturing can revolutionize your production process. With greater precision, speed, and automation, these machines are essential for companies looking to stay competitive in the modern manufacturing landscape. By integrating high-accuracy optical sorting equipment into your workflow, you’ll reduce waste, improve quality, and ensure your Cable Accessories meet the highest industry standards.

Optimizing your Cable Accessories production with cutting-edge optical sorting technology not only enhances quality control but also boosts overall efficiency. At VES Gujarat-India, we are committed to helping manufacturers stay at the forefront of industry advancements. Contact us today to learn more about how our optical sorting solutions can elevate your production line!

For more information visit https://vesindia.org/products/machine-vision-system/fasteners-inspection-machine.aspx