Glass table fasteners-auto parts automatic optical inspection measurement sorting machine camera vision system

Type of Job / Parts / Object supported for inspection and dimension measurement

fasteners, auto parts, washer, nut, bolt, screw, rivet, sleeve, spacer, stud, pins, bearing cage, bullet, cartridge, cartridge case, bullet jacket cups, ammunition, insert, molding insert, electrical terminals, electrical connector, cable gland, cable accessories, plastic parts, rubber ball, o ring, copper seam, spring, precious parts, aeronautical part, turning parts, custom parts, special parts, forging parts.

Type of Machine

glass plate, glass disc, glass table, slotted plate, slotted disc, slotted table, conveyor belt

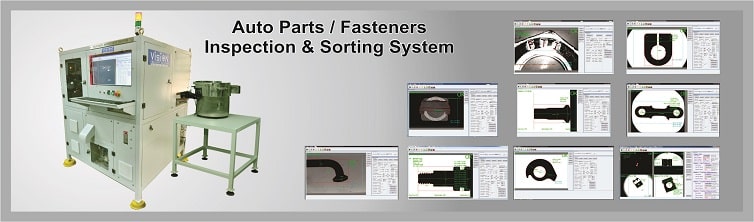

Fasteners Inspection Sorting System is high speed, 100% measuring and fasteners inspection

Sorting systems. The Fasteners Inspection Sorting System enables highly precise 2D and/or 3D measurements, of high volume parts and components before they are introduced into production.Fasteners Inspection

Sorting System will help with eliminating costly process jams and malfunctions

Through various Inspection and sorting techniques, equipment and algorithms, we

use experienced camera machine vision inspection and sorting engineering

capabilities to enhance systems to their full potential. By implementing

well-designed vision systems, machine process control and feedback is enhanced

Automatic Sorting Machine, Automatic Sorting System, Industrial Sorting Machine

to provide the data needed to automate most processes.

A manufacturer of components for the automotive, electric , ejection mould,

insert and precious industry needed an automated inspection and sorting solution to labor intensive process.

Camera Vision Inspection Systems can perform repetitive tasks faster, more accurately, and with greater consistency over time than humans.

VES design, develop, manufaturer,

Supplier and

Camera Vision Inspection Sorting Systems for a perfect quality inspection,

future-proof and flexible to get trouble-free production.

Fasteners Inspection Sorting System features

- Fasteners Inspection Sorting System , with easy to use standard software, are leading the way toward zero defect quality.

- Fasteners Inspection Sorting System can be used to inspect Nuts,rods,washer fastener,O-ring,special parts.

- Optional cameras are available to check for internal threads and surface imperfections.

- Vision can be added to detect defects like missing internal threads, nylon ring presence, and missing crimp.

- Fasteners Inspection Sorting System allows great detail of I.D. threads and the detection of very small defects like; Chips in threads, weld splatter, a single damaged thread, torn threads, reamed threads, short or missing thread(s).

- Windows based software makes part setup easy, and allows for part storage and retrieval.

- Developed software as per indian market requirement

- Run on Very High Speed FPGA based Motion Control Card and other controller

- User Friendly

Fasteners Inspection Sorting System can inspect:

Optical Inspection and Sorting Machine

|

|

Washer, Fasteners, Core, Insert, Plastic Cap, Nut sorter, bolt sorting, nut sorting machine, washer sorting machine, automatic

glass table insepction and sorting machine |

|

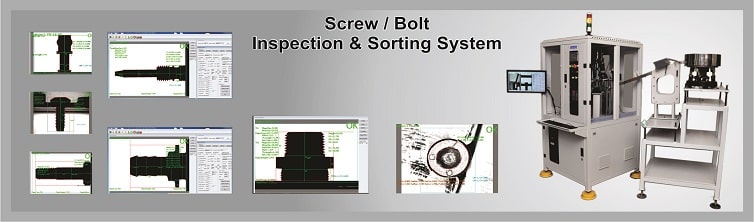

screw sorter, bolt sorter, screw sorting machine, screw sorting machines, bolt sorting machine,

automatic slotted table insepction and sorting machine |

|

Eddy Current Sorting machinee

VES produces Eddy current sorter, Eddy current sorting machines which are suitable for screws, nuts or cylinder-type objects |

|

VES sorting machines offers Rod/ Stud sorting machines, we developed PSV Sorting Machine for different rod/stud parts |

|

Technical Specification: Fasteners Inspection Sorting System

| Description |

Parameter |

| No. of Camera |

1 to 4 |

| Vision System |

High resolution lanses and light source |

| Software |

Accuvision Pro |

| Speed |

200 ~ 1000 pcs/min |

| Operating system |

WINDOWS XP/7 |

| Weight |

750 kgs |

| Accuracy |

0.010mm |

| Size |

2.1 X 1.4 X 1.9 Meter |

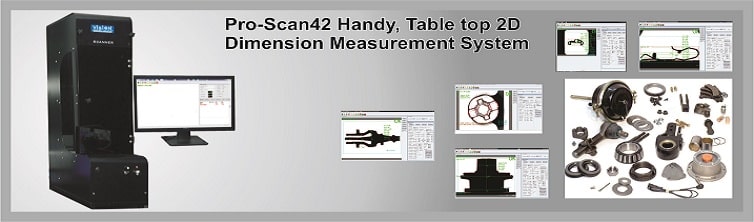

Enhance your manufacturing process with our advanced fasteners inspection and sorting machine. This machine utilizes a video camera system for accurate measurement and sorting of various fasteners. Keywords: fasteners inspection, optical measurement, sorting machine.

Our auto parts optical inspection system is designed for precise measurement and sorting, ensuring quality control in production lines. Keywords: auto parts inspection, optical sorting machine, measurement sorting.

Optimize your production with our washer inspection machine, utilizing video camera technology for accurate sorting and measurement. Keywords: washer inspection, optical sorting, measurement sorting machine.

Ensure the quality of nuts with our advanced inspection and sorting machine, which features video camera technology for reliable measurement. Keywords: nut inspection, optical measurement, sorting machine.

Our bolt inspection system combines precision and efficiency, utilizing video camera technology for optimal sorting and measurement. Keywords: bolt inspection, optical sorting machine, measurement sorting.

Revolutionize your production with our screw optical inspection and sorting machine, designed for accurate measurement and sorting. Keywords: screw inspection, optical measurement, sorting machine.

Enhance the quality control process with our rivet inspection machine, which offers precise measurement and sorting capabilities. Keywords: rivet inspection, optical sorting machine, measurement sorting.

Our sleeve inspection machine uses advanced video camera technology for accurate measurement and sorting, ensuring quality assurance. Keywords: sleeve inspection, optical measurement, sorting machine.

Utilize our spacer inspection machine for reliable sorting and measurement, leveraging video camera technology for optimal performance. Keywords: spacer inspection, optical sorting, measurement sorting machine.

Ensure quality with our stud inspection machine, designed for precise optical measurement and sorting using advanced camera technology. Keywords: stud inspection, optical measurement, sorting machine.

Our pins inspection machine utilizes state-of-the-art video camera technology for effective measurement and sorting solutions. Keywords: pins inspection, optical sorting machine, measurement sorting.

Our bearing cage inspection measurement sorting machine utilizes advanced video camera technology for accurate sorting and measurement. Ideal for quality control in manufacturing.

Experience precise sorting with our bullet optical inspection measurement sorting machine. Perfect for ensuring the highest quality standards.

The cartridge optical inspection measurement sorting machine is designed for efficient inspection and sorting, enhancing productivity in production lines.

Ensure precision with our cartridge case optical inspection measurement sorting machine, tailored for quality assurance in ammunition manufacturing.

Our bullet jacket cups optical inspection measurement sorting machine offers advanced sorting solutions for optimal quality control.

Utilize our insert optical inspection measurement sorting machine for precise measurement and sorting of components in your production line.

Enhance your manufacturing process with our molding insert optical inspection measurement sorting machine, ensuring quality and efficiency.

Optimize your quality control with our electrical terminals optical inspection measurement sorting machine, designed for precision and reliability.

Our electrical connector optical inspection measurement sorting machine ensures that each component meets the highest quality standards.

Increase efficiency in your production line with our cable gland optical inspection measurement sorting machine, perfect for high-volume manufacturing.

The cable accessories optical inspection measurement sorting machine is designed for quick and accurate inspections, improving workflow in your facility.

Ensure quality in plastic manufacturing with our plastic parts optical inspection measurement sorting machine, ideal for various production needs.

Plastic Parts Inspection Machine

The plastic parts inspection measurement sorting machine uses video camera technology for precise optical inspection. This machine efficiently sorts and measures plastic components to ensure quality control in manufacturing.

Rubber Ball Inspection Machine

Our rubber ball inspection measurement sorting machine is equipped with advanced video camera systems for accurate optical measurement. It effectively sorts rubber balls based on quality and specifications.

O Ring Inspection Machine

The video camera-based O ring inspection measurement sorting machine provides reliable optical sorting and measurement. This machine is essential for ensuring the quality of O rings used in various applications.

Copper Seam Inspection Machine

With our copper seam inspection measurement sorting machine, manufacturers can achieve precise optical measurement and sorting of copper seams, enhancing product quality and consistency.

Spring Inspection Machine

The spring inspection measurement sorting machine employs video camera technology for thorough optical inspection. It ensures springs meet quality standards before reaching the market.

Precious Parts Inspection Machine

This machine specializes in inspecting and sorting precious parts using advanced optical inspection technology, guaranteeing the integrity and quality of high-value components.

Aeronautical Parts Inspection Machine

Designed for precision, our aeronautical parts inspection measurement sorting machine ensures that components meet stringent aerospace industry standards through rigorous optical measurement and sorting.

Turning Parts Inspection Machine

The turning parts inspection measurement sorting machine utilizes cutting-edge video camera technology for effective optical inspection and sorting of turning parts, enhancing operational efficiency.

Custom Parts Inspection Machine

For manufacturers of custom parts, our inspection measurement sorting machine offers tailored solutions for precise optical measurement and sorting, ensuring quality and performance.

Special Parts Inspection Machine

Our special parts inspection measurement sorting machine is designed to handle unique requirements, providing reliable optical sorting and measurement for specialized applications.

Forging Parts Inspection Machine

Utilizing advanced video camera technology, our forging parts inspection measurement sorting machine delivers thorough optical inspection and sorting, ensuring the highest quality in forged components.

Vision Embesoft Solution is a leading manufacturer and supplier of Automatic Sorting Machines in Ahmedabad, Gujarat, India. Our Automatic Sorting Machines are essential in quality control and processing, designed to inspect and sort items such as fasteners, nuts, bolts, washers, precious parts, automobile components, grains, plastics, and food. This system ensures compliance with quality standards by sorting products based on defects, dimensions, geometry, shape, texture, and size. The machine integrates advanced technologies, including high-resolution cameras, precise lighting, and intelligent software, to meet the specific needs of your production line. We offer a range of sorting solutions tailored to various budgets, capacities, and quality standards.

Our Automatic Sorting Systems are designed for diverse industries to ensure precise sorting and quality control. Manufactured by Vision Embesoft Solution in Ahmedabad, Gujarat, India, these systems are optimized to handle items like fasteners, automotive parts, grains, plastics, and more. With cutting-edge technology involving cameras, lighting, and software, the sorting system classifies products based on defects, dimensions, shape, and texture. Our extensive product line supports multiple budget and capacity requirements, ensuring you get the ideal solution for your quality control processes.

Vision Embesoft Solution offers Industrial Sorting Machines in Ahmedabad, Gujarat, India, that are essential for any high-precision processing operation. These machines sort and inspect a variety of items such as fasteners, automobile components, and food products, meeting stringent QC and QA requirements. The machine leverages advanced vision technologies, including high-speed cameras and specialized software, to sort by dimensions, geometry, and other critical parameters. Our range of products is adaptable to different production needs, from budget-friendly options to high-capacity solutions for superior quality assurance.

Our key products include: Fastener Inspection Machine, Auto Optical Micro Screw Sorting Machine, Quality Control Vision Systems, Automated Vision Inspection Systems, Vision Inspection Equipment, and Auto Optical Nut Inspection Machines. We provide solutions for machine vision, measurement systems, coordinate measuring machines, robotics, and automation. These systems are crucial for quality inspection across industries, supporting enhanced product quality and operational efficiency. Key applications include sorting systems, computer vision and machine learning, automated inspection systems, and more.

Vision Embesoft Solution offers comprehensive vision and sorting solutions, including Automated Optical Inspection Machines, Deep Learning for Vision Systems, 3D Machine Vision Technologies, and Surface Inspection Systems. Our products serve clients across major Indian cities, including Ahmedabad, Rajkot, Surat, Jamnagar, Vadodara, Mumbai, Pune, Kolkata, New Delhi, Bangalore, Hyderabad, Jaipur, Visakhapatnam, Kanpur, Lucknow, Chennai, Coimbatore, and Cochin, delivering quality inspection and automated solutions nationwide.